The Ultimate HVAC Energy Savings Guide: how to meet sustainability targets and improve efficiency

Lately, we’ve been hearing a lot from property managers who oversee commercial offices that sustainability targets are quickly becoming a top priority. Any opportunity to slash energy consumption is quickly seized. The problem many of them come to us with, however, is that it can be difficult to know where to start. In commercial and large residential buildings, HVAC (heating, ventilation, and air-conditioning) systems account for a significant portion of annual energy consumption, but there’s no easy ‘upgrade’ button you can press to make your system more efficient.

With that being said, many HVAC systems we inspect are still running old, tired fans which work day-in, day-out to blow air through neglected and mostly dust-blocked air filters. Many businesses seek better indoor air quality and better energy savings, but ignore the easiest solutions. In other cases, we see systems set up incorrectly or ventilation rates that are obsolete with the current layout of a building or office space. The UK Green Building Council reports that many commercial buildings use up to twice as much energy as originally modelled, largely due to controls, commissioning, and operational practices (UKGBC, Closing the Performance Gap), which not only brings a tear to any building manager’s eye, it also harms sustainability scores, drives up costs, and can make it difficult to achieve Green Buildings certifications (e.g., BREEAM, LEED, and WELL).

In this article, we’ll discuss all the different routes you can take to improve the energy efficiency of your HVAC system to reduce substantial overhead costs, improve carbon performance, reduce waste, and meet those sustainability targets everyone’s grasping for.

Professional HVAC Cleaning: Clear Ducts means Less Energy Usage

Routine HVAC servicing and ductwork cleaning is commonly seen as a way to improve indoor air quality, but recent peer-reviewed research shows it can also play a central role in energy optimisation.

Research-Backed HVAC Performance Post-Cleaning

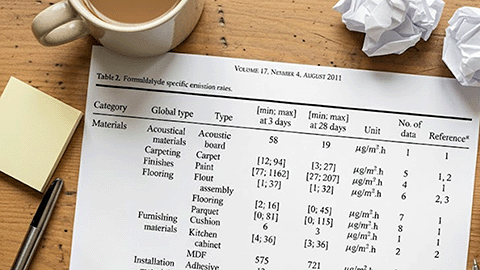

A large multi-climate study published in Energy and Buildings (Vol. 328, 2025) found that professionally cleaned HVAC systems experienced dramatic improvements in both fan energy use and airflow performance. Key findings include:

- 41 – 60% reduction in fan/blower energy consumption.

- 10 – 46% increase in supply airflow!

These improvements occur because dust and debris create resistance, forcing fans to work harder and increasing overall system load. If you want your fans to last longer, make their job easier — have a professional clear out all the dust and grime forcing your fans to work overtime.

Results of HVAC Cleaning on Energy Expenditure

Enhanced airflow doesn’t just reduce the strain on equipment — it also means less wasted energy, lower electricity consumption, and smaller carbon footprints. Clean systems run more predictably and require less backup power, further trimming operating costs. We recommend that routine HVAC servicing should therefore be part of a holistic maintenance strategy, and the first step in reducing costs, delivering both healthier air and tangible energy savings long into the future.

Ultraviolet Cleaning: An AHU's Best Friend

UVC, or UVGI, (Ultraviolet germicidal irradiation) systems are typically installed in AHUs of high-risk areas where a sterile environment is crucial, like hospitals (for HTM 03-01) or nursing homes. They’re placed inside the AHU, near the coils where microorganisms tend to accumulate in the tight gaps. This UVC technology actively destroys the bacteria, viruses, and fungi that get trapped here and also reduces the build-up of biofilm making it much more difficult for the coils to become blocked.

UVGI takes some initial capital to purchase and install, but it is a trusted method to keep AHUs clear and air clean in spaces where air quality is especially important. Though UV systems are just an added benefit to any ventilation system, they are very effective at keeping components cleaner for longer, therefore reducing the likelihood of filters or coils causing airflow issues (resulting in excessive energy use) or components breaking down entirely (requiring new components and increasing landfill waste), so UVGI could be seen to pay back some of what it costs to install, all the while reducing the impact on our environment.

TM44 Inspections: Compliance with Energy Savings

A TM44 inspection is a legal requirement in the UK to ensure your AHU or ventilation system meets energy efficiency standards, however many people don’t consider that this legal requirement can actually be incredibly useful for building managers. Under the Energy Performance of Buildings Regulations, systems with a combined cooling output over 12 kW must be inspected every five years to remain compliant, so why not take that opportunity to learn about your ventilation system, upgrade underperforming components, and bring your energy efficiency to the best possible level?

What does TM44 deliver?

- Regulatory compliance: Avoid fines (£800 or more per building in 2025) and ensure your HVAC systems meet statutory requirements.

- Identifying inefficiencies: Certified assessors pinpoint issues such as poor controls, blocked airflow, and outdated components that drive up energy use.

- Actionable recommendations: Reports include tailored suggestions to improve settings, controls and maintenance practices — and the best part is the ripple benefit to efficiency.

TM44 Energy and Cost Benefits

Government-linked data and independent providers report that implementing TM44 recommendations can reduce energy use by 30–40 per cent across a system, with simple control changes alone often saving 10–20 per cent. These savings not only cut bills but also help buildings contribute to sustainability targets by reducing carbon emissions.

Filter changes: Crucial for Performance but often Forgotten

Regular air filter changes are one of the simplest yet most effective ways to improve HVAC energy efficiency while protecting indoor air quality. When filters become clogged with dust and particulates, airflow is restricted, forcing fans and motors to work harder and consume more electricity. The US Department of Energy reports that replacing dirty filters can reduce HVAC energy use by 5 – 15%, simply by restoring proper airflow and system balance (US DOE, Energy Saver, 2023). Similarly, ASHRAE guidance notes that pressure drops across blocked filters are a common cause of unnecessary fan energy demand and premature equipment wear (ASHRAE Handbook – HVAC Applications).

Beyond energy savings, clean filters help maintain stable ventilation rates, improve thermal comfort, and extend the life of coils and fans, reducing maintenance costs and unplanned downtime. As part of a sustainable building strategy, routine filter replacement delivers fast payback, lower carbon emissions, and consistently healthier indoor environments — with minimal disruption and investment.

Optimise your Energy-Consumption with a Professional Condition Report

Regular condition reports and structured ventilation validation provide the technical foundation for implementing HVAC improvements. Condition surveys identify degraded components, air leakage, fouled coils, and control faults that quietly undermine efficiency. Ventilation validation (AKA ventilation verification) confirms that systems are delivering the correct airflow rates and meeting current standards, helping duty holders demonstrate compliance while uncovering opportunities to optimise performance. Combined with proactive servicing, these measures extend equipment life, reduce breakdown risk, and prevent inefficient operation from becoming embedded in daily use.

Through ventilation validation, we can determine how air is distributed and controlled throughout the HVAC system and the building itself. Airflow balancing ensures that the right volume of air reaches each zone, preventing over-ventilation in some areas and under-ventilation in others. Poorly balanced systems often run fans at higher speeds than necessary, increasing electricity consumption and accelerating wear on motors and bearings. By restoring design airflow rates, buildings can reduce fan energy demand, improve thermal comfort, and stabilise indoor air quality with immediate efficiency gains.

Air Quality Monitoring, Data-Driven Ventilation, and Control Strategies

At ARM Environments, we’re strong advocates for always staying in-the-loop with your air quality, as it provides the fundamental data required to make any effective improvements to your air quality or HVAC system. In the past, we’ve been contacted by multiple different clients for issues they only detected through consistent monitoring — they would’ve never known there was an issue otherwise, and it meant we could reach them before any real problems did actually arise.

Control strategies — such as demand-controlled ventilation (DCV), use real-time data from indoor CO2 sensors to help regulate HVAC energy consumption. ARM’s very own Air Quality Determined Ventilation (AQDV) system builds upon this idea of demand-controlled ventilation. Our technology uses real-time indoor and outdoor data to determine the best possible times to ventilate a space each day, meaning rush hours and local construction sites don’t impact the air quality inside. Importantly, it also ensures fans aren’t running for extended periods, flooding the space with pollutants all day long. AQDV works logically — it chooses to ventilate during the cleanest times of the day because that’s when it needs to work for the least amount of time, thereby cutting energy consumption drastically. Paired with high-efficiency EC fans, AQDV is a highly-anticipated choice for many businesses, particularly in polluted areas like central London.

What are the benefits of Data-Driven Ventilation?

According to independent building systems research, control logic techniques like DCV can reduce HVAC energy use by up to 88 per cent while keeping carbon dioxide levels within healthy ranges.

As buildings become more connected and data-rich, these strategies are increasingly accessible and cost-effective for facility managers. Watching your air in real-time via IAQ monitors also offers the opportunity to easily log air quality data, providing valuable insights into any potential issues (both internal, like a filter getting blocked, or external, like emissions from particularly heavy traffic) to protect the wellbeing of your staff and ensure your system continues to work effectively and efficiently. For commercial office spaces or high-end buildings, it also offers increasingly important data on energy usage and material waste which are key sustainability measures.

Choosing MVHR Units for Heat Recovery

Mechanical Ventilation with Heat Recovery (MVHR) systems offer one of the most effective ways to improve HVAC energy efficiency while maintaining high indoor air quality. Though this is an expensive option for existing buildings, many modern new-builds are choosing MVHR for their energy efficiency. By extracting warm, stale air and transferring its heat to incoming fresh air, MVHR units significantly reduce the amount of energy required for space heating, particularly in well-sealed commercial and modern residential buildings.

The Energy Saving Trust reports that a correctly specified and commissioned MVHR system can recover up to 90 per cent of the heat from extracted air, cutting overall ventilation heat losses by around 50 per cent in typical buildings (Energy Saving Trust, Mechanical Ventilation with Heat Recovery, 2023).

How can MVHR units reduce my energy bills?

Beyond direct energy savings, MVHR supports wider sustainability and compliance objectives by lowering carbon emissions associated with heating demand. The UK Green Building Council highlights that ventilation heat losses can account for 30–50 per cent of total space-heating energy in airtight buildings, making heat recovery a critical lever for meeting net-zero targets (UKGBC, Building Performance & Energy Use). From an operational perspective, MVHR also improves comfort by delivering pre-warmed, filtered fresh air at consistent temperatures, reducing draughts and stabilising internal conditions.

When integrated with balanced airflow commissioning, intelligent controls, and regular servicing, MVHR systems deliver long-term reductions in energy use and overhead costs, while strengthening indoor air quality performance. For organisations pursuing lower running costs alongside environmental responsibility, heat recovery ventilation represents a practical, future-proof investment in both efficiency and sustainability. MVHR is a must have when a new ventilation system is required.

The next steps to improve your HVAC efficiency

HVAC energy savings and sustainability aren’t achieved through a single fix. The most successful approaches combine regulatory compliance, professional cleaning, regular servicing, and intelligent control strategies. Together, these tactics can significantly reduce energy use, lower overhead costs, and contribute to broader environmental targets without sacrificing indoor air quality.

By turning services like TM44 inspections, ductwork cleaning, and AHU servicing into proactive investments, organisations can build more efficient, resilient, and sustainable buildings that deliver both economic and environmental value.

If you’re looking for the next steps to reach your sustainability targets or just want to cut down on your overheads by giving your outdated ventilation system some TLC, get in contact with one of the air quality experts at ARM Environments. We’ll discuss the best approaches tailored to your setting, goals, and budget.