Everything You Need to Know About Fire and Smoke Dampers

Though critical pieces of kit for both indoor ventilation and fire safety, the installation, testing and maintenance of fire and smoke dampers are not often talked about in building and facilities management. In this article we will explore the best practices around dampers, how to stay compliant with regulations and standards so you can ensure the health and wellbeing of your occupants.

What are fire and smoke dampers?

Fire and smoke dampers are fail safes that prevent the spread of fire through an HVAC system. They are shutters installed in the ductwork and can be closed both manually and automatically when fire or smoke are detected by sensors. They are subject to building regulations and standards in the UK, designed to ensure the safety of occupants in buildings.

These regulations and standards are typically set out in documents such as the Building Regulations and guidance documents published by organisations like the British Standards Institution (BSI), the Building Research Establishment (BRE) and the Building and Engineering Services Association (BESA).

The difference between fire and smoke dampers

Fire dampers and smoke dampers are two different types of dampers used in building HVAC (heating, ventilation and air conditioning) systems to enhance fire safety. While they both play crucial roles in fire protection, they have distinct purposes and functions.

Fire dampers

Purpose: Fire dampers are designed primarily to prevent the spread of fire and hot gases through ductwork and air distribution systems. They act as barriers in the ducts and automatically close when exposed to high temperatures.

Function: Fire dampers are triggered by a fusible link or thermal sensor that melts at a specific temperature (usually around 165°F or 74°C). When this link melts, the damper's blades close, sealing off the duct and preventing the fire from spreading to other parts of the building.

Location: Fire dampers are typically installed at duct penetrations through fire-rated walls and floors, as well as in other critical locations where fire compartmentalisation is required.

Operation: They are passive devices that remain open during normal HVAC system operation and only close during a fire event.

Smoke dampers

Purpose: Smoke dampers are primarily designed to control the movement of smoke within a building during a fire. While they can also serve as fire barriers, their primary function is to contain smoke.

Function: Smoke dampers can be controlled manually or automatically, and they are often linked to a building's fire detection and alarm system. When smoke is detected, the dampers close to prevent the smoke from spreading to other parts of the building.

Location: Smoke dampers are typically installed in ducts that pass through fire-rated walls, floors or partitions, as well as in ducts serving areas where smoke containment is critical, such as stairwells and elevator shafts.

Operation: Smoke dampers can be actively controlled, allowing for more precise management of smoke movement. They may partially close to maintain a pressure differential and prevent smoke from travelling to unaffected areas.

Both types of dampers are essential components of fire protection systems in buildings and are often used in combination to enhance fire safety and protect building occupants. Their installation and maintenance are subject to building codes and regulations to ensure they function effectively during a fire emergency.

UK regulations and standards relating to dampers

The following are the most relevant regulations and standards. For a deeper discussion and to learn more about how to comply with regulations and standards relating to fire and smoke dampers, read our article How to Comply: UK Smoke & Fire Damper Regulations and Standards.

Building Regulations

The primary regulations governing fire and smoke dampers in the UK are found in Part B (Fire Safety) of the Building Regulations. The relevant document is Approved Document B: Fire Safety. This document provides guidance on fire safety in buildings, including the use of fire and smoke dampers.

British Standards

The installation and maintenance of fire and smoke dampers are often guided by British Standards. One of the key standards related to this is BS 9999:2017 "Code of practice for fire safety in the design, management, and use of buildings." This standard provides recommendations for fire safety strategies in buildings, including the use of fire and smoke dampers. We go deeper into this standard in our article, BS 9999: Fire Safety & Fire Dampers.

When purchasing fire dampers, look out for those compliant with BS EN 1366-2:2015 “Fire resistance tests for service installations, fire dampers”.

BESA DW145

In 2010 BESA introduced its guidance: “DW/145: Guide to Good Practice for The Installation of Fire and Smoke Dampers”. The standard is intended to ensure that fire and smoke dampers are installed correctly and in accordance with the relevant regulations and guidelines. It provides detailed guidance on the selection of fire and smoke dampers, the installation of the dampers in ductwork systems, and the testing and commissioning of the dampers to ensure that they are working correctly.

In order to clear up some lingering confusion from outdated guidance, BESA will be updating DW145 at the BESA Conference on 12th October 2023.

NAAD22

This document gives guidance on the appropriate design, selection, installation, testing & commissioning, maintenance and inspection of fire dampers. It was launched on 5 October 2023 at the HVR Awards. See more on NAAD22 here.

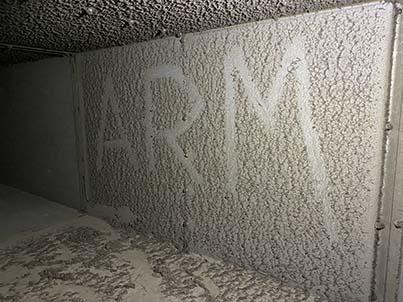

Where should fire dampers be installed?

Fire dampers are an essential part of fire protection systems and should be strategically placed in various locations in a building, including in the HVAC system’s duct penetrations, AHUs and kitchen exhausts, to effectively contain a fire and prevent the spread of fire and smoke through the ductwork. These are the 6 key locations where fire dampers should be installed.

- Duct Penetrations: Fire dampers are commonly installed at duct penetrations – a point where a ductwork system passes through a wall, floor or ceiling that separates different compartments or areas within a building – through fire-rated walls and floors. These dampers automatically close in the event of a fire, sealing off the duct and preventing the spread of fire and smoke between different compartments or zones of a building.

- Air Handling Units (AHUs): Fire dampers should be installed both upstream and downstream of air handling units, including the supply and return ducts. This helps prevent the spread of fire or smoke through the HVAC system, which can circulate these hazards to other parts of the building.

- Kitchen Exhaust Systems: In commercial kitchens, fire dampers are often installed in the exhaust ductwork to prevent fires from spreading into the exhaust system and subsequently into the building. These dampers are typically referred to as kitchen exhaust fire dampers.

- Stairwell and Elevator Shafts: Fire dampers may be installed in ducts that run through stairwells and elevator shafts to maintain the integrity of these escape routes during a fire.

- Smoke Control Systems: Fire dampers can be a part of smoke control systems, especially in buildings with atria, large open spaces or complex layouts. They help control the movement of smoke during a fire emergency.

- Fire-Rated Walls and Barriers: Fire dampers are used in conjunction with fire-rated walls and barriers to maintain the fire resistance rating of these structures. They should be installed wherever HVAC ducts pass through such walls and barriers.

- Hazardous Areas: In some cases, fire dampers may be installed in ducts serving areas with a higher fire risk, such as chemical storage rooms or industrial facilities.

It's important to follow local building codes and regulations, as well as the recommendations of fire protection engineers and experts, when determining the specific locations and requirements for fire damper installations in your building. Regular inspection, maintenance, and testing of fire dampers are also crucial to ensure their proper functioning in the event of a fire.

How to maintain fire dampers

Maintaining fire dampers is crucial to ensure they function correctly during a fire emergency. Fire damper maintenance should be conducted by trained professionals following specific procedures and guidelines.

Important Note: Fire damper maintenance procedures may vary depending on the manufacturer's recommendations, local building codes and regulations. Always follow the specific instructions provided for the fire dampers in your building.

1. Notify Authorities: Inform relevant authorities and building occupants about the maintenance schedule to prevent any confusion or alarm during the process.

2. Access the Fire Damper: Locate the fire damper you intend to maintain and ensure that it is accessible. This may require removing access panels or cover plates.

3. Visual Inspection: Start by conducting a thorough visual inspection of the fire damper and its surroundings.

Check for any signs of damage, corrosion, or wear on the damper blades, frame, and surrounding ductwork. Ensure there are no obstructions, debris, or dirt inside the damper or ductwork that could impede its operation. Inspect the fusible links or thermal sensors, if present, to ensure they are intact and undamaged.

4. Operational Testing: Test the operation of the fire damper to ensure it opens and closes correctly.

Use a screwdriver or power tool (as recommended by the manufacturer) to gently close and open the damper blades. Observe whether the blades move freely and fully close when the damper is triggered.

If the damper has a fusible link or thermal sensor, you may need to heat it manually (using a heat gun or other approved method) to simulate a fire condition and trigger the damper closure. Ensure that the damper closes and latches securely.

5. Cleaning: Clean the damper blades and surrounding areas as needed. Remove any dirt, dust, or debris that could hinder the damper's operation.

6. Lubrication (if applicable): Some fire dampers may require lubrication of moving parts. If recommended by the manufacturer, apply the appropriate lubricant to ensure smooth operation.

7. Documentation: Record the date of the maintenance, the damper's location, and the results of the inspection and testing in a maintenance log. Keep these records for compliance and future reference.

8. Repairs and Replacements: If any issues, damage or deficiencies are identified during the maintenance process, take appropriate action to repair or replace the fire damper components as necessary to ensure proper functionality.

9. Reassemble and Secure: Reattach the access panel or cover plate securely after completing maintenance.

10. Regular Maintenance Schedule: Establish a regular maintenance schedule for fire dampers, typically on an annual basis, but consider more frequent maintenance if your building's conditions warrant it.

11. Compliance: Ensure that your maintenance procedures align with local building codes, regulations and manufacturer recommendations.

Remember that fire damper maintenance is critical for fire safety compliance and maintaining the reliability of these devices. Always follow the specific maintenance guidelines provided for the fire dampers in your building and consult with qualified professionals if you are unsure about any aspect of the process.

How to test fire dampers

Testing fire dampers is a critical part of fire safety maintenance to ensure they function properly when needed.

Important: Testing fire dampers should be performed by trained professionals who understand the specific requirements and safety precautions. It's essential to consult local building codes and regulations, as well as manufacturer guidelines, as testing procedures may vary.

1. Notify Authorities: Before testing a fire damper, ensure that appropriate authorities and building occupants are informed of the testing schedule to avoid unnecessary panic or confusion during the process.

2. Gather Equipment: You will need:

- Screwdrivers or power tools (for access panel removal)

- Inspection mirror or camera (optional but helpful)

- Smoke or heat detectors (for certain tests)

- A ladder or scaffolding (if the damper is located in a high area)

3. Access the Damper: Locate the fire damper you want to test. Fire dampers are typically installed in the ductwork within walls, floors, or ceilings. Access the damper by removing the access panel or cover plate.

4. Visual Inspection: Conduct a visual inspection of the fire damper and surrounding areas to check for any signs of damage, obstructions, or debris that might interfere with its operation.

5. Functional Test: To perform a functional test, follow these steps:

- With the access panel removed, locate the damper blades or louvers.

- Use a screwdriver or power tool (as recommended by the manufacturer) to gently close and open the damper blades. Observe whether the blades move freely and fully close when the damper is triggered.

- If the damper has a fusible link or thermal sensor, you may need to heat it manually (using a heat gun or other approved method) to simulate a fire condition and trigger the damper closure. Ensure that the damper closes and latches securely.

6. Reconnect the Access Panel: After testing, reattach the access panel or cover plate securely.

7. Documentation: Record the date of the test, the damper's location, and the results of the test in a maintenance log. This documentation is essential for compliance and future reference.

8. Additional Testing: Depending on local regulations and manufacturer recommendations, you may need to perform other tests, such as air pressure differential testing or smoke or heat detector testing, if applicable to your specific fire damper.

9. Regular Inspection and Maintenance: Fire dampers should be inspected and tested regularly, typically on an annual basis, by qualified professionals. Routine inspections help ensure that the dampers remain in good working condition.

Repairs and Replacements: If any issues or deficiencies are identified during the testing or inspection, take appropriate action to repair or replace the fire damper as needed to maintain its functionality.

Fire damper testing is crucial for fire safety compliance and ensuring that these devices operate effectively when a fire emergency occurs. Always follow local building codes, regulations, and manufacturer guidelines for fire damper testing and maintenance. Keep detailed records of all inspections, tests, and maintenance activities as proof of compliance with regulatory requirements.

How often should fire dampers be tested?

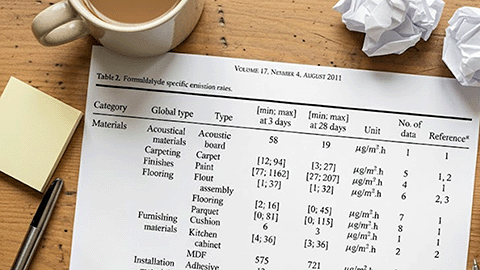

In the United Kingdom, fire damper testing and maintenance requirements are typically outlined in building regulations and standards, such as those provided by the Building Regulations and the British Standards Institution (BSI). The frequency of fire damper testing and inspection can vary depending on the specific application, building type, and local regulations. However, here is a general guideline for fire damper testing frequency in the UK.

Initial Testing: Fire dampers should be tested after installation to ensure they are functioning correctly and in compliance with regulations.

Regular Testing: After the initial test, fire dampers in the UK are typically subject to regular testing and inspection. The recommended frequency for routine testing is usually at least once every 12 months.

Additional Testing: In some cases, fire dampers may require more frequent testing, especially if they are located in areas with higher fire risks or where dust and debris accumulation can occur. In such instances, more frequent inspections, such as every six months, may be necessary.

Critical Areas: In critical or high-risk areas, where the failure of fire dampers could have severe consequences, more frequent testing and maintenance may be mandated. This determination should be made based on risk assessments and local regulations.

Follow specific building regulations and guidance in your area, as well as any recommendations from the local fire safety authority, to determine the precise testing frequency for fire dampers in your building. Always follow the manufacturer's guidelines and recommendations for testing and maintenance, as these may provide specific instructions for your damper models.

Our services

As experts in air quality and compliance, we offer professional fire damper testing and maintenance services which you can access here. If you have any questions, feel free to get in touch — let's discuss how we can help keep your building fire safe.