UV vs HEPA Filtration – Retrofit Energy Consumption Evaluation

The CIBSE Covid-19 ventilation guidance recommends operating the air handling units on full fresh air to mitigate the spread of the Covid-19 virus within the workplace environment.

We all understand that this is a very energy intensive way to operate HVAC plant, that is not sustainable. There are many air purification technologies in the market that can be integrated into all HVAC systems, however, in an energy conscious world, it is imperative that the long-term energy consumption is evaluated as we continue to strive for a sustainable world.

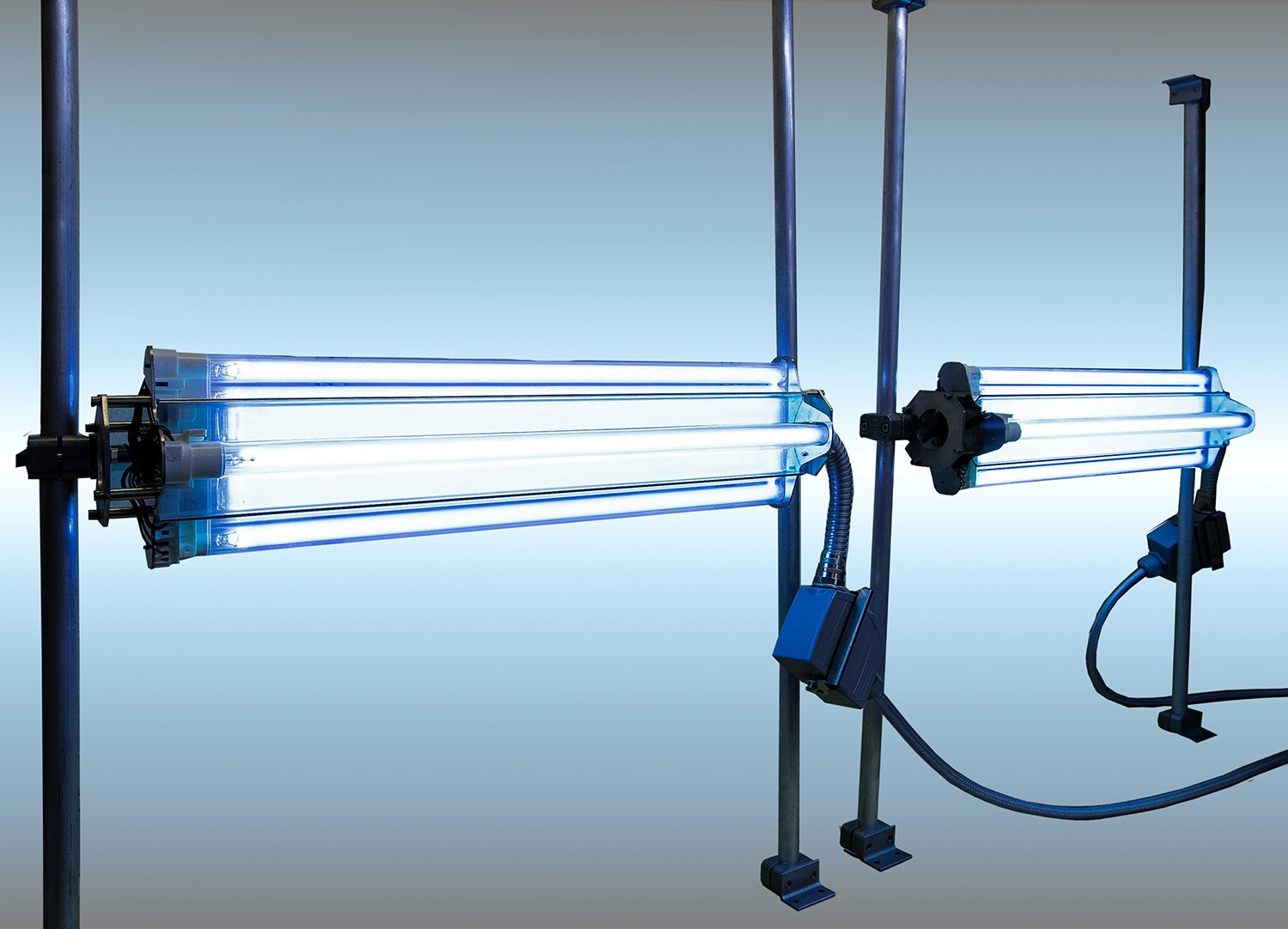

UV-C can be implemented into ventilation systems and is recognised to possess a very powerful germicidal effect capable of inactivating a wide spectrum of microorganisms, such as viruses, bacteria, fungi, and yeast. The UV-C lamps consume a significant amount of energy dependant on the required reduction in certain microorganisms.

For an in-depth explainer on ultraviolet germicidal irradiation (UVGI), read our article The UVGI Explainer: How it Works, Benefits and Solutions.

There are different grades of HEPA filters that can be installed within an air handling unit. The grades vary based on the percentage of particles that are 0.1 microns in diameter that are trapped. The pressure drop of a typical H13 grade HEPA filter is much higher than a standard ePM2.5 55% filter (M6) which understandably increases the electrical consumption of the fan motor within the AHU.

ARM Environments carried out a theoretical assessment of the energy consumption of the two technologies to allow building owners, facilities managers, and consultants to make informed decisions about these technologies when it comes down to energy.

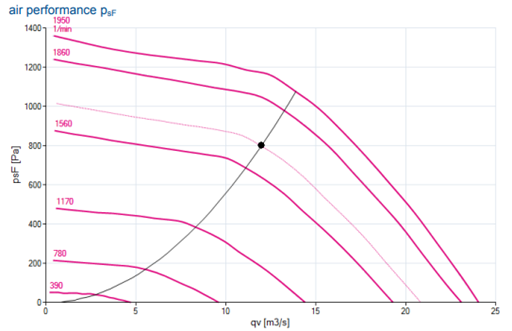

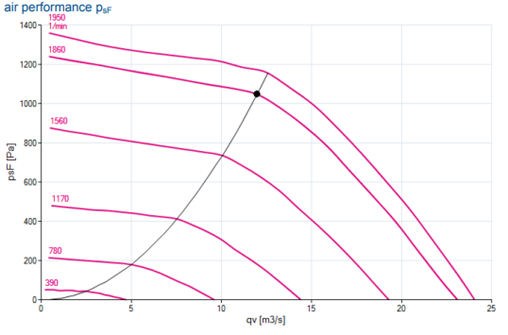

Based on an office application with an air handling unit providing a constant 12m³/s of air to the building for the 1000 occupants (12l/s per person). The IE5 EC plug fans would be consuming approximately 13000 watts based on a total pressure of 800Pa at 12m³/s.

For this assessment, we have based our criteria on operating hours of 24 hours a day for 365 days of the year, with a requirement to reduce the Covid-19 virus by 99% within 12m³/s of air. Based on these criteria and a velocity of 2m/s within the AHU, the total energy consumption of the UV-C lamps would be approximately 1240 watts. As the UV lamps have a negligible pressure drop, we would expect no significant increase in electrical consumption from the fan motor with the UV lamps installed. The UV lamps would need replacing after 9,000 hours of continuous operation so thought must be given to the ongoing maintenance cost. If the lamps are not replaced in line with manufacturers recommendations, the efficacy of the lamps will degrade over time.

Using the same criteria as above, the original pressure drop through a H13 HEPA filter with a 99.95% efficiency, is 250Pa based on a velocity of 2.3m/s with a maximum recommended final pressure drop of 500Pa. The lifecycle of the HEPA filter will vary depending on the pre-filtration installed and its specific filter efficiency. With an additional 250Pa added to the system for the fan motor to overcome, whilst still providing the same volume of air, the electrical consumption of the fan would increase from approximately 13000 watts to 17200 watts.

Retrofitting HEPA filters into an existing ventilation system is not always feasible due to maximum velocity limitations for HEPA filters. Existing AHUs may also require fan upgrades to ensure the duty of the AHU is not compromised when increasing the system pressure drop. When incorporating HEPA filters into a new air handling unit, the fan and motors can be sized correctly along with ensuring velocities are within the design constraints.

Please see below for our summary of results table from our theoretical assessment of these air cleaning technologies. The fans used to ascertain the increase in electrical consumption were the latest Ziehl-Abegg IE5 EC plug fans selected as a 6x fan array.

|

Technology |

Additional Energy Consumption (kWh) |

Yearly Energy Consumption (kW) |

Total Yearly Energy Cost (£0.11) |

Technology Efficiency |

|

UV-C |

1.24 kWh |

10,862.4 kW |

£1,194.86 |

99% |

|

HEPA |

4.2 kWh |

36,792 kW |

£4,047.12 |

99% |

The difference between the operational cost of HEPA filtration compared to UV-C is rather significant with an overall increase of 238%.

Pre-HEPA Fan Curve

Fan Curve post-HEPA Install

If you would like assistance or guidance on how to sustainably operate your HVAC plant whilst complying with IAQ regulations, please get in touch with the team at ARM Environments for a free consultation.