Optimise AHU costs, improve indoor air quality

MaintainAway

Considering buying a new air handling unit?

Or refurbishing with like-for-like components?

Our MaintainAway product offers a third option. Upgrading to smart IoT components saves energy, and removes the need for regular cleaning and maintenance.

A small increase in CapEx saves you a lot of OpEx.

Award-winning

indoor air quality

solution

MaintainAway is a two time award winner:

ASHRAE's Technology Awards 2023 – Smart Buildings

HVR Awards 2023 – Indoor Air Quality Initiative of the Year

Affordable, optimal, sustainable

Cheaper overall:

Inspecting each AHU component, cleaning the coils & drain pans, and not being notified of when to replace filters, can rack up your costs quickly. The smart IoT components of MaintainAway enable you to focus your spend elsewhere.

Optimise energy consumption:

Sticking with the filters provided by AHU manufacturers & maintenance contractors is seldom energy efficient. G4 pre-filters and F7 final filters typically selected with most AHUs use more energy than necessary.

Reduce waste:

Typically, pre-filters are changed every 3 months whether they need to be or not. Filters are typically chosen on cost rather than lifespan. MaintainAway models filter selection using outdoor air quality data, to minimise your filter changes.

How MaintainAway

Saves Energy and Costs

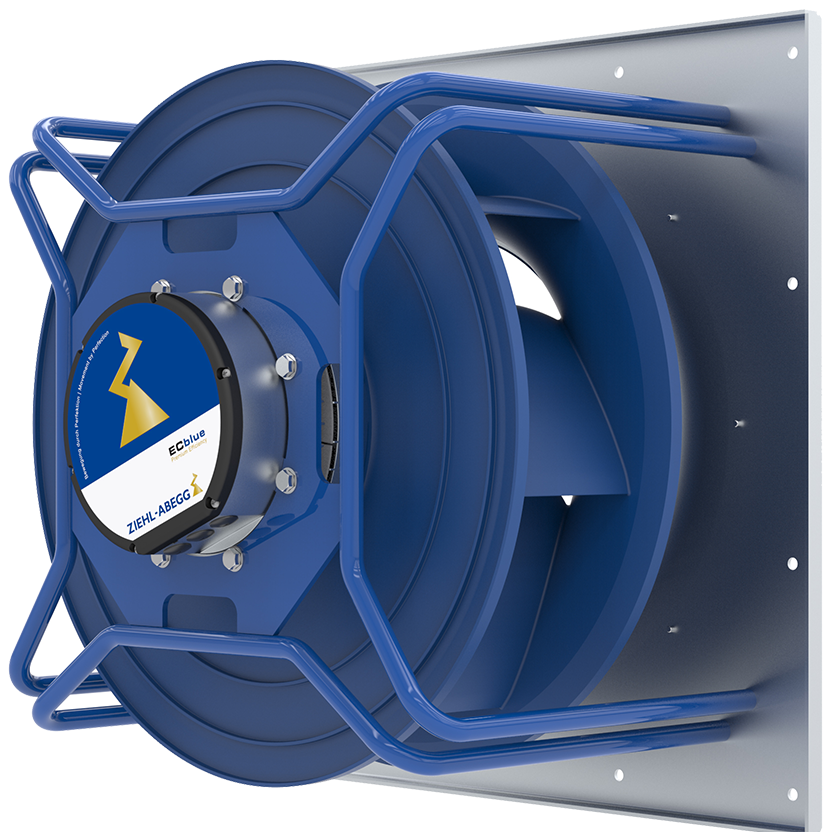

Belt-free fans

EC Fans and direct drive switch fans have no drive belts to inspect or maintain

Ultra-long life filters

Low energy ePM10 and ePM1 filters last longer and have low pressure drop – replacement filters can be selected and supplied via subscription using our Smart Filtration Management solution

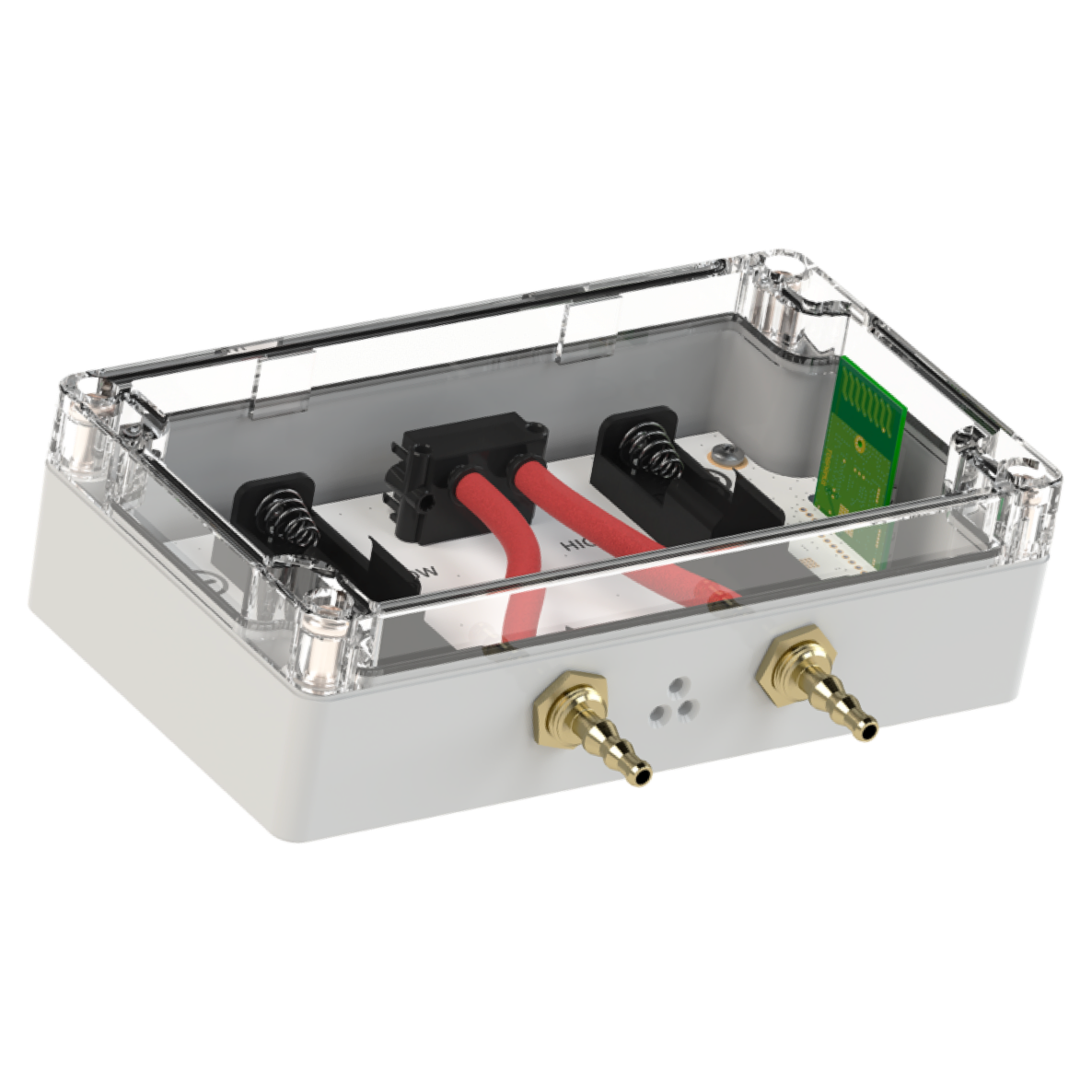

Automated filter monitoring

Filter condition is monitored remotely through pressure drop sensors. Any problems, like a filter blowout, will be alerted immediately

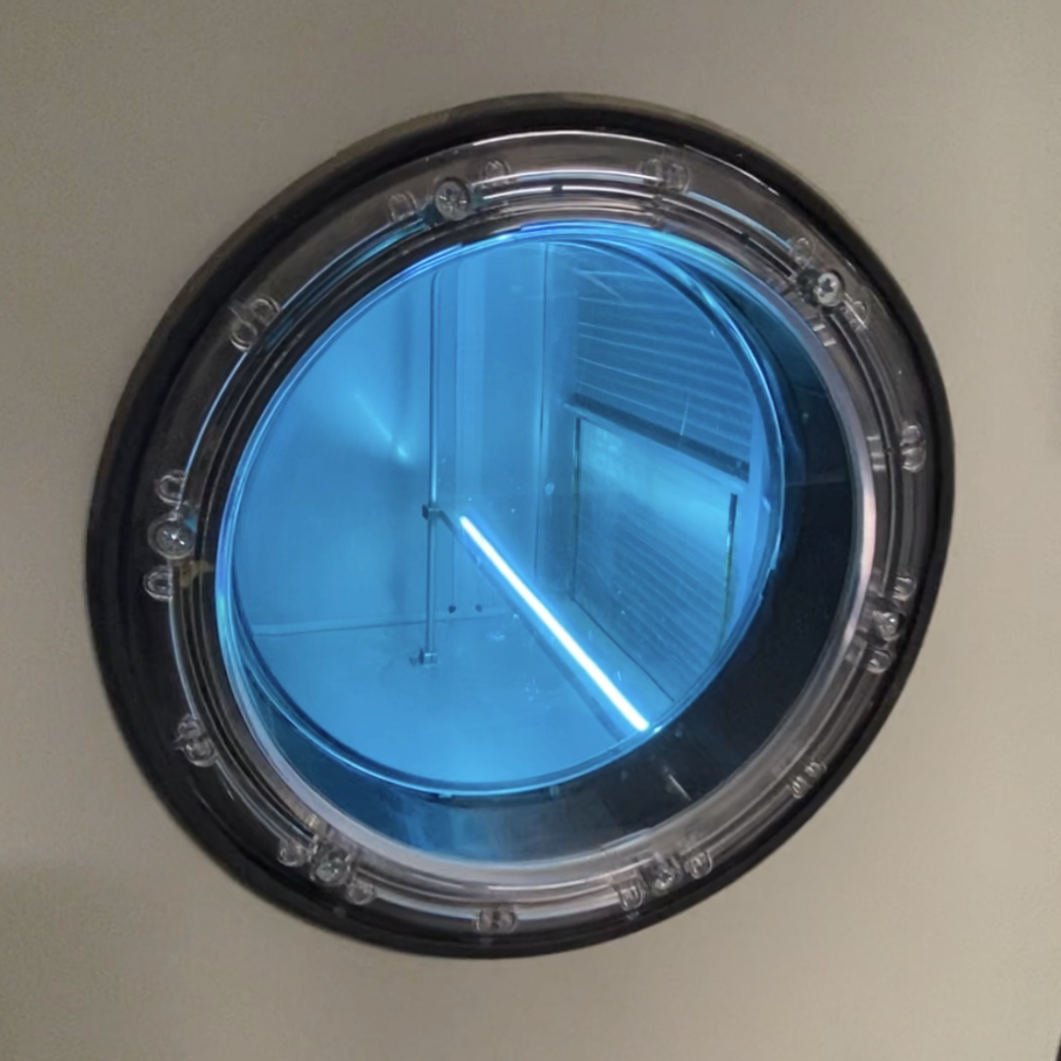

UVGI coil & pan cleaning

The cooling coils and drain pans are cleaned with UV light – there is no need to inspect or clean them

Easier Maintenance

| Typical AHU Maintenance | MaintainAway |

| Motor drive belt inspections | Direct-drive EC fans remove the need for belts |

| Motor inspection | Remote monitoring of status, inc run hours and vibration |

| Motor lubrication | Motor lubrication not required, sealed bearings |

| Cooling coil inspections | Coil irradiated with UVGI to prevent biofilm growth |

| Cleaning drain pan | Drain pan irradiated with UVGI to prevent biofilm growth |

| Record filter pressure drop value | Filter pressure drop remotely monitored in cloud |

| Filter condition inspection | Filter inspection not required – automated notifications |

| Replace pre filters (3 monthly) | Ultra long-life pre-filters used |

Optimised Operation

| Typical Operation | MaintainAway |

| TimeClock operation | Demand-driven |

| Possibly CO2 driven | Indoor air quality driven |

| Mixing on temperature | Mixing proportion based on temperature & IAQ |

| Filters selected via rule of thumb | Filters selected to Eurovent 4/23 |

| Maintenance on a planned basis | Data driven maintenance based on usage |

| Faults fixed as discovered | Faults identified in advance via data-feed |

One of our AHU specialists will get in touch

©2021 ARM Environments • All rights reserved